The Original Mattress Factory Tour

At The Original Mattress Factory, we invite you to take a tour of our factories where you can see for yourself how we make mattresses right — and built them to last.

We start with the best materials:

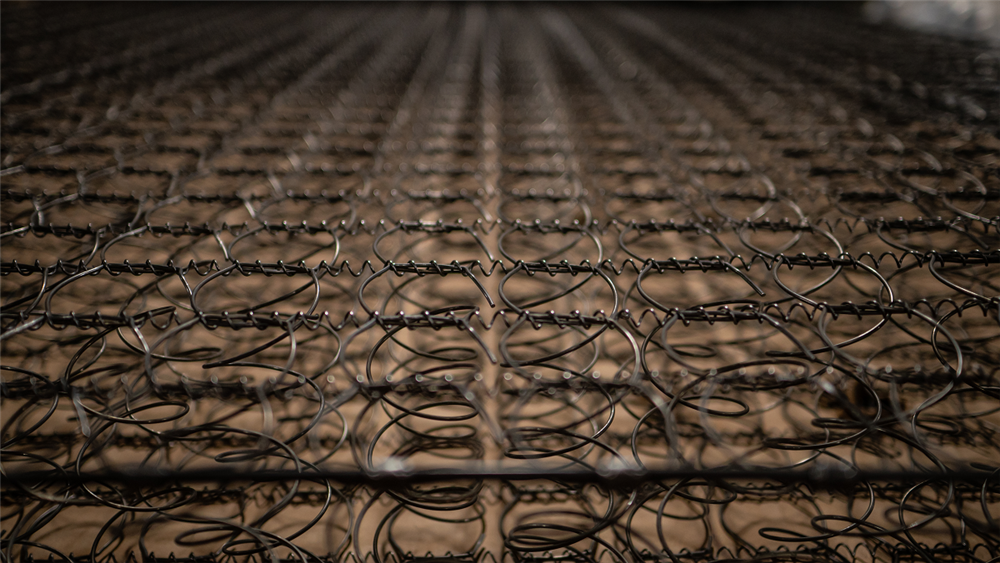

- Heavy-gauge springs for extreme durability

- Renewable cotton for ultimate softness and breathability

- High-density foam and damask fabrics quilted together for ultimate comfort

- Amish-built, real working box springs

Then we build every mattress by hand.

Each layer added determines how soft or firm the mattress will feel. And many of our mattresses are two sided, allowing you to flip them regularly to extend the life of the mattress.

The tape edge is sewn on with the utmost attention to detail to put the finishing touches on the mattress.

And you can’t forget about the box spring! Each box spring cover is hand sewn in our factories.

Those covers are then hand upholstered onto our Amish-built, real working box springs.

Each product is then individually inspected before it is wrapped, sealed, and prepared for delivery.

You can visit one of our 11 factory locations to take the tour for yourself. Stop by the nearest factory location for a tour today.